Logistics Automation: Maximum Efficiency Guide + Examples

Imagine the chaos if all the trucks, ships, and airplanes had to be managed manually without any logistics automation systems – endless paperwork, misplaced documents, delays, errors, and miscommunications. The result would be a much slower and less efficient global economy.

Logistics automation has made it possible to keep up with the sheer volume of products and supplies moving across borders every day. Bustling distribution centers and trade hubs with containers being loaded and unloaded and amid all this activity, there are advanced logistics automation systems working tirelessly to ship and receive thousands of items each hour without delays or errors.

This is just a tiny glimpse of the things logistic automation can fix for business owners. If you are a venture or an organization operator looking to get into logistic automation to boost your operations, then you are just at the right spot.

This article talks about what logistic automation is, its different types, and some real-world examples that you can learn from. By the end of this article, you will know the strategies to maximize the benefits of logistic automation for a more synchronous and profitable outcome.

4 Major Types Of Logistics Automation

Logistics automation is the use of technology and software to streamline and optimize logistics operations and improve the efficiency of supply chain management. It revolutionized the way businesses manage their supply chains.

This opened doors to more precise and expedited transport and handling of goods while keeping everything under economic check. Of course, we can’t deny the fact that it streamlines efficiency. To understand its wide spectrum of activities, we will have to dig deeper and start with the 4 major types of logistic automation.

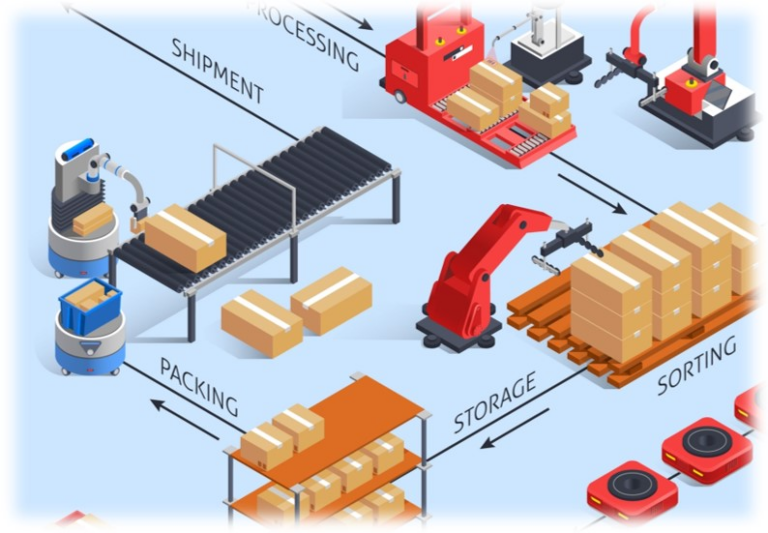

Warehouse Automation

Warehouse automation is a process that involves the use of advanced technologies to optimize and streamline various warehouse operations like inventory management, order picking, and shipping. They use advanced technology like conveyors, robots, and sensors for this. Some examples of warehouse automation technologies include:

Automated Guided Vehicles (AGVs)

AGVs are mobile robots that move products from one location to another within the warehouse. They can navigate autonomously, using sensors and software to avoid obstacles and follow predefined paths.

Automated Storage & Retrieval Systems (ASRS)

ASRS uses computer-controlled machines and automated storage systems to store and retrieve products in a warehouse. These systems can be vertical or horizontal and they use robotics to move products to and from storage locations.

Goods-To-Person (GTP) Systems

GTP systems bring the products to the workers rather than the workers moving around the warehouse. It transports the goods to a picking station where workers can quickly and efficiently pick the products for shipment.

Transportation Automation

Transportation automation systems use technology to optimize the transportation of goods from one location to another. These systems can optimize delivery schedules and dispatch vehicles more efficiently. It also improves overall supply chain visibility by allowing companies to monitor the movement of goods throughout the supply chain. Some of the examples are:

Route Optimization Software

This software optimizes transportation routes to reduce fuel consumption, improve delivery times, and increase efficiency. The software takes traffic conditions, weather, road blockades, and other factors into account to find the most efficient route.

Real-Time Tracking

These systems use GPS technology for complete control over the real-time tracking of the location of vehicles and products. This information is used to provide customers with accurate delivery times and helps logistics companies optimize their delivery routes.

Predictive Analytics

Predictive analytics are used to identify potential delays or problems in the supply chain and take corrective action before they occur. It also helps companies to anticipate demand and optimize transportation operations to meet that demand efficiently. To reduce delays, you can use Vector’s Pickup and Delivery Cloud solution, getting the drivers out of the facility in under 20 minutes.

Get best practices for reducing dwell time

Last-Mile Delivery Automation

Last-mile delivery automation leverages advanced software and eliminates manual human input to minimize errors in the delivery of goods to their final destination, like a customer’s home or business. If we look at it, the last mile is mostly an expensive and time-consuming part of the delivery process. Some examples include:

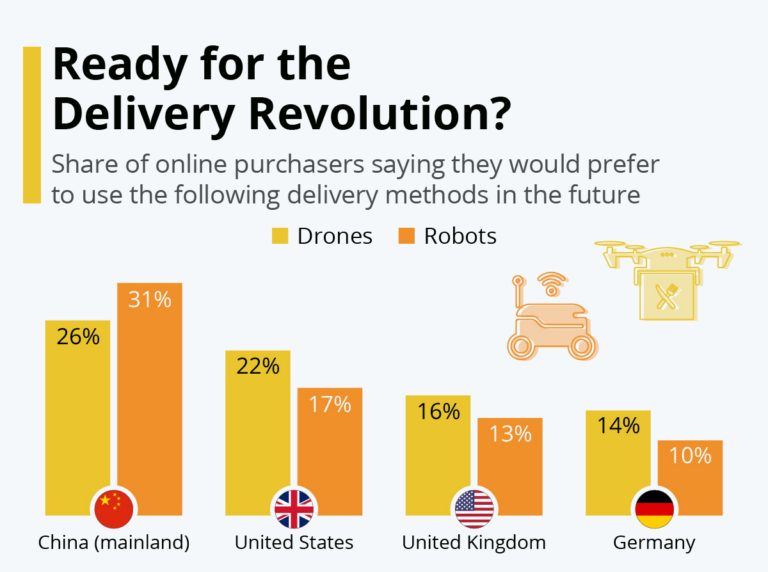

Drones

Drones can be programmed to follow specific delivery routes and drop off packages directly to customers, bypassing the need for a human driver. Reduced delivery times and costs, especially in urban areas are some of the benefits of using drone technology.

Robots

Delivery robots can navigate sidewalks and streets and deliver goods directly to customers’ doorsteps. They can carry packages of various sizes. This technology is particularly useful for delivering small packages and groceries where the delivery distance is short.

Lockers

Lockers are automated storage systems that can be used to store and retrieve products for customers. Shopping centers and train stations are some of the public places that house such lockers. First, the package is delivered to the locker, then the customer gets a code or a barcode to access the locker and retrieve the goods.

Yard Automation

Seamless logistics operations heavily rely on the effectiveness of yard management. The utilization of yard automation offers a wide array of tools and advanced technologies that work together to optimize processes, allocate resources more efficiently, and ultimately boost overall operational efficiency. Here are some key benefits:

Real-Time Yard Visibility

Yard automation systems integrate sensors, RFID technology, and data analytics to provide real-time visibility into yard operations. You can monitor the location and status of trailers and containers to ensure efficient utilization of yard space. Real-time visibility helps in better planning and coordination, reducing delays and optimizing workflow.

Smart Yard Space Utilization

By analyzing the volume and types of goods, as well as the expected flow of vehicles, the yard automation system can suggest the most efficient allocation of yard space. This ensures that space is utilized effectively, reducing congestion, and enabling smoother operations.

Digital Documentation & Reporting

Yard automation allows for digital documentation and reporting, eliminating the need for manual paperwork. Electronic records of incoming and outgoing shipments, inventory levels, and other important data are seamlessly captured and stored within the system. This digitalization reduces errors, enhances data accuracy, and enables easy access to critical information for analysis and decision-making.

While we’ve covered the major types of logistics automation, merely knowing them isn’t enough. To help your business effectively implement this technology, here are exceptional real-world examples to consider and learn from.

Schedule a FREE yard audit with Vector

Get Inspired With These 4 Real-World Examples Of Logistics Automation

Let’s take a look at some real-world examples of logistics automation that will show you how they can help streamline operations and improve customer service in distribution centers.

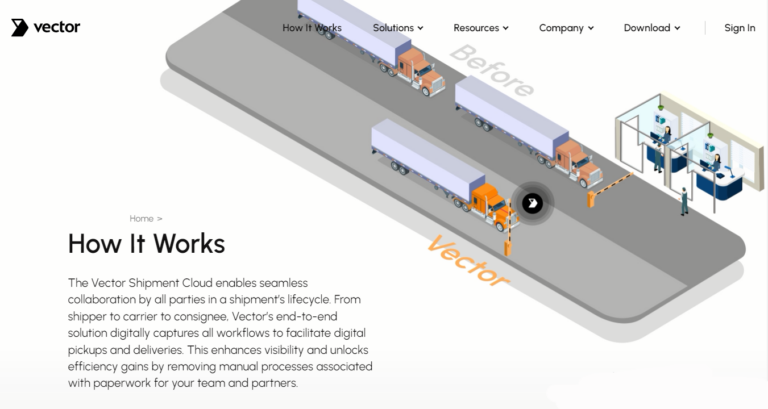

Vector Pickup & Delivery Cloud

The Vector Shipment Cloud is a digital end-to-end solution for seamless collaboration between shippers, carriers, and consignees. Our solution allows for digital pickups and deliveries and removes the need for standalone data capture software. It also enhances visibility and efficiency gains by eliminating manual processes associated with paperwork.

The Vector Shipment Cloud has 3 steps:

- Digital check-in

- Replacing paper-based records with digital records

- Completing delivery workflows

When a driver arrives at a facility, they can use their phone, a kiosk, or an SMS to check in. This means they are no longer required to manage paper documents or pagers and can avoid the time-consuming manual data entry process that comes with them. Instead, our platform gives them an electronic bill of lading (eBOL) which they can sign electronically.

Vector Shipment Cloud reduces dwell time, increases productivity, and provides an accurate log of when drivers arrive and leave facilities. Our platform’s real-time visibility

- Shows where trailers are and if they are empty

- Provides insights into all activities within the yard

- Provides performance metrics to measure dwell time and detention fees

Vector streamlines the check-in process, reduces the average warehouse’s time by more than 30 minutes per load, and provides automated entry and exit.

To learn more about Vector Shipment Cloud, get in touch with us now.

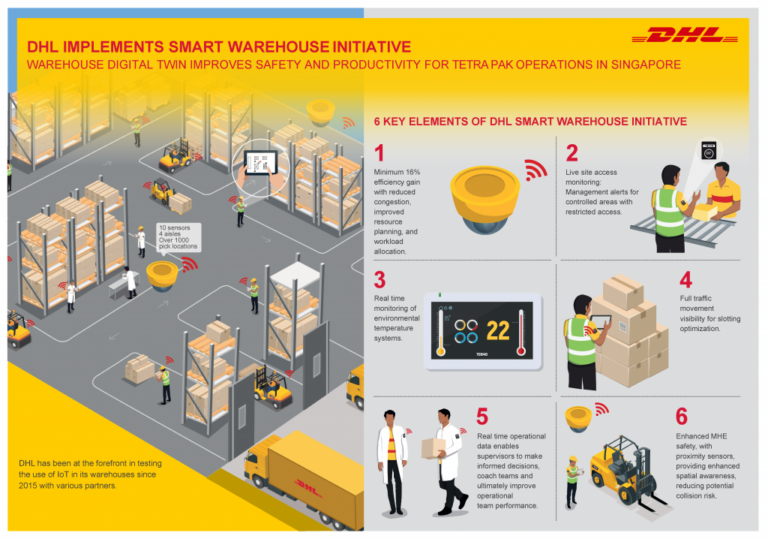

DHL Smart Warehouse

DHL is another logistics company that has embraced logistics automation to the fullest. The company’s Smart Warehouse system uses a combination of robotics, sensors, and logistics automation software to manage inventory and streamline warehouse operations.

One of the key features of the DHL Smart Warehouse system is its use of sensors to monitor inventory levels and track the movement of products around the warehouse. This way, DHL gets real-time visibility into its inventory and makes adjustments quickly when necessary.

The DHL Smart Warehouse system also includes AGVs that move products around the warehouse. These AGVs are controlled by logistics automation software that optimizes their movements and ensures that products are moved efficiently.

UPS On-Road Integrated Optimization & Navigation (ORION)

UPS On-Road Integrated Optimization & Navigation (ORION) is a logistics automation system designed to optimize UPS delivery routes. It uses algorithms and machine learning to analyze delivery data and identify the most efficient routes for drivers. ORION factors in variables such as traffic, weather, and package weight to optimize routes, reducing fuel consumption and improving delivery times.

The ORION software has been successful in reducing UPS’s operating costs and increasing its delivery efficiency. When delivery routes are optimized, the number of miles driven by the drivers is automatically reduced significantly. This is how UPS has saved millions of dollars in fuel costs.

FedEx SameDay Bot

The FedEx SameDay Bot or Roxo as they named it, is a delivery robot designed to transport small packages and goods to customers’ doorsteps. The robot uses artificial intelligence and machine learning algorithms to navigate sidewalks and crosswalks and avoid obstacles and pedestrians.

Roxo was developed to address the growing demand for faster and more efficient last-mile delivery options. By using this robot, FedEx can provide same-day delivery service for a range of products, including food, medicine, and retail items.

The SameDay Bot has numerous benefits, including reducing delivery times, improving efficiency, and reducing the need for human labor to perform repetitive tasks. The SameDay Bot can also communicate with customers, sending notifications and updates about their delivery status.

With insights gained from how major industry players use logistics automation for maximizing output, it’s time to put them together and formulate strategies that you can adopt to improve your supply chain operations.

4 Proven Strategies To Maximize Logistics Efficiency

The logistics industry is responsible for managing the flow of goods from the point of origin to the point of consumption. With the ever-so-high demand for quick and reliable delivery of products, efficient logistics has become the need of the hour. Here are some strategies you can use to get the best out of it.

Conduct A Thorough Analysis Of Current Logistics Operations

The first step in maximizing logistics efficiency is to conduct a thorough analysis of current logistics operations. This analysis should include an evaluation of the current transportation network, inventory management system, and warehouse operations. This analysis targets to pinpoint specific areas that need to be improved or taken care of while formulating an optimal strategy.

Evaluate The Transportation Network

The transportation network is the backbone of the logistics sector so naturally, it is of utmost importance to ensure it operates flawlessly and efficiently. Here are a few factors to acknowledge while evaluating the transportation network.

- Capacity Utilization: Assess the capacity utilization of each mode of transport. This analysis should consider the percentage of available capacity that is being utilized.

- Delivery Time: Evaluate the time the goods take to be transported from the point of origin to the point of consumption. This analysis should be done for each mode of transport.

- Transportation Costs: Analyze the transportation costs associated with each mode of transportation. This analysis should factor in the cost per mile, the cost per unit of weight, and the overall cost per shipment.

Here’s a useful read on the challenges faced by the transportation industry.

Evaluate The Inventory Management System

While transportation is the backbone of the logistics sector, the inventory management system is no less. This makes it absolutely essential to ensure that it is operating to its full potential. To evaluate the inventory management system, assess the following:

- Stock-Out Rate: Evaluate the rate at which inventory gets out of stock. This analysis will include the percentage of time that inventory is out of stock.

- Inventory Turnover: Analyze the inventory turnover rate. This analysis should consider the number of times inventory is sold and replaced over a given period.

- Inventory Carrying Cost: Analyze the cost associated with carrying inventory. This analysis should consider the cost of storage, insurance, and other related costs.

Evaluate The Warehouse Operations

Warehouse operations are the final component of the logistics sector and it is important to ensure that they operate efficiently. To evaluate the warehouse operations, assess the following:

- Order Accuracy: Evaluate the percentage of orders that are fulfilled accurately.

- Order Fulfillment Time: Analyze the time it takes to fulfill an order end to end. This analysis should factor in the time it takes to pick, pack, and ship an order.

- Warehouse Utilization: Consider the amount of space currently used. Then evaluate the amount of space that is still available and the additional space that is needed.

Identify Areas That Can Be Automated

Once you are done with the evaluation part, the second step in maximizing logistics efficiency is to put the collected data to use and identify areas that can be automated. Automation can help to reduce manual labor, improve accuracy, and increase efficiency. Several areas within the logistics sector can be automated, including the following:

Evaluate The Transportation Network

Inventory management is one of the most important areas of the logistics sector. It can be challenging to manage inventory manually, especially for those who deal with a large volume of products. To optimize the inventory control systems and maximize efficiency, here are a few suggested solutions:

- Adopt a Just-in-Time (JIT) System: This reduces inventory carrying costs by ordering inventory only when it is needed. This brings down inventory levels and minimizes the risk of stock-outs.

- Conduct Regular Inventory Audits: Conducting regular inventory audits identifies discrepancies and reduces the risk of stock-outs. This optimizes inventory levels and minimizes carrying costs.

- Implement Automated Inventory Management: It can minimize manual errors, improve accuracy, and save time. It can be done through barcoding, RFID technology, or other automated systems.

- Use Inventory Management Software: Use this to track inventory levels, forecast demand, and manage orders. This can reduce stock-outs and overstocking, which can lead to significant cost savings.

- Improve Supply Chain Collaboration: Improving collaboration between suppliers, manufacturers, and distributors can reduce lead times and improve inventory turnover. This can be done using cloud-based platforms and real-time data sharing.

Transportation Management

Transportation management is another area within the logistics sector that can be automated to maximize logistics efficiency. To optimize the transportation network and maximize logistics efficiency, here are a few solutions to implement:

- Optimize Capacity Utilization: Consider consolidating shipments or using a third-party logistics provider (3PL) that specializes in optimizing capacity utilization.

- Negotiate with Carriers: This reduces transportation costs. Logistics managers can negotiate better rates based on the volume of shipments or long-term contracts.

- Diversify Transportation Modes: This helps reduce transportation costs and improve delivery times. For instance, using air freight for high-priority shipments and ocean freight for low-priority shipments can optimize the transportation network.

- Implement Performance Metrics: Implementing performance metrics can track transportation costs, delivery time, and capacity utilization. By monitoring these metrics, logistics managers can identify areas of improvement and make necessary adjustments.

Looking to cut down on transportation expenses? Check out this guide on different strategies for reducing your costs.

Warehouse Management

To address the issues identified from the evaluation of warehouse operations, here are solutions to implement:

- Optimize Warehouse Layout and Space Utilization: Reorganize the warehouse layout to improve the flow of goods and increase storage capacity. Adopt best practices such as slotting, cross-docking, and multi-level racking.

- Train Warehouse Staff: Proper training for warehouse staff can improve order fulfillment time and accuracy. Staff should be trained in efficient picking and packing techniques, as well as the optimum use of technologies.

- Implement Quality Control Measures: To improve order accuracy, quality control measures should be put in place such as random checks of orders before shipment. This can help catch errors before they reach the customer.

- Implement Warehouse Management Systems (WMS): A WMS streamlines warehouse operations by automating tasks like inventory tracking, order picking, and shipment tracking. This reduces errors and improves efficiency.

Create A Roadmap For Implementation

Creating a roadmap for implementation is the third strategy that you can use to maximize logistics efficiency. It will provide a clear plan for implementing the strategies identified in the previous steps. Let’s take a detailed look:

Identify Goals

The first step in creating a roadmap for implementation is to identify goals. You need to define what you want to achieve with your logistics operations. Most businesses target to reduce the time for processing orders, increase delivery accuracy, or cut down on transportation expenses.

Define Tasks

Once the goals have been identified, the next step is to define tasks. By identifying the tasks and creating a workflow, you can get closer to achieving your goals. For instance, if the goal is to reduce the time it takes to process orders, the tasks will include automating certain processes, reorganizing the warehouse layout, or implementing new technologies.

Assign Responsibilities

Assigning responsibilities is the next step in creating a roadmap. Identify who will be responsible for each task and ensure that they have the necessary resources and support to complete them. This can include assigning a project manager, providing training, or hiring additional staff.

Define Timeline

Defining a timeline is another important step in creating a roadmap. Establish a realistic timeline for completing each task and achieving the goals. The timeline should factor in budget, resources, and potential obstacles. Setup clear deadlines to ensure that the implementation stays on track.

Monitor Progress

Finally, continuously monitor progress throughout the implementation process. You should track the completion of tasks, measure their impact on efficiency, and make adjustments as necessary. This may involve regular meetings with stakeholders, reporting on progress to management, and making adjustments to the roadmap as needed.

Train Employees On New Systems & Processes

Training employees is the fourth and last strategy for maximizing logistics efficiency. So when businesses implement new technologies or processes, remember that these systems cannot work to their fullest unless the employees are trained to use them effectively. Let’s discuss how to train employees on new systems and processes in detail.

Communicate The Benefits

The first step in training employees on new systems and processes is communicating the benefits. Employees may be resistant to change or skeptical about the value of new systems and processes. Explain how the new systems and processes will benefit them and the company as a whole.

Provide Comprehensive Training

Providing comprehensive training is the next step in training employees on new systems and processes. You should provide employees with the necessary knowledge and skills to use the new systems and processes effectively. This may include classroom training, hands-on training, or online training modules.

Encourage Feedback

Employees will have questions, concerns, or suggestions about the new systems and processes. Encourage them to share any of these. A culture where employees feel comfortable providing feedback and are encouraged to do so has a positive outcome in the long run. This feedback can help identify areas for improvement and ensure that the new systems and processes are being used effectively.

Monitor Performance

You must track how well employees are using the new systems and processes and measure their impact on efficiency. This can involve setting performance metrics and conducting regular performance reviews. Provide feedback to employees and recognize their efforts to use the new systems and processes effectively.

Provide Ongoing Support

Finally, providing ongoing support is crucial in ensuring that employees are using the new systems and processes effectively. This way, introducing newer systems can have more acceptance and help employees maintain their skills. Refresher training, access to user manuals, and technical support all come under the umbrella of ongoing support.

Conclusion

People may think logistics automation is a complex and overwhelming series of processes. It can be true to some extent but its benefits far outweigh the complexities. The fact of the matter is that automation accelerates the process through efficiency, accuracy, quality, and whatnot.

It doesn’t matter if you are a solo player and own a small operational warehouse or logistics industry giant, logistics automation systems are for everyone and can be customized based on their needs. The only thing that matters is the future of your business growth and that is focused on ever-so-amplifying automation.

We at Vector believe in simplifying logistical operations with our ever so evolving advanced tech. It’s time you streamline communication and gain unprecedented visibility into your operations with our solution which is dedicated to simplifying logistics and making them more accessible to everyone. Get a free trial and see what the future of logistics holds for your business.